Lifting slings are essential tools in various industries, particularly in construction, manufacturing, and logistics, where heavy loads need to be safely moved. Single-use lifting slings, which are designed for one-time applications, are gaining popularity due to their convenience and cost-effectiveness. However, selecting the right sling for your operations is a crucial decision, as it directly impacts safety, efficiency, and compliance with regulatory standards. In this article, we will discuss the key considerations to keep in mind when choosing a single-use lifting sling for your operations single use lifting sling.

Understanding Single Use Lifting Slings

A single-use lifting sling is designed to be used for one lifting operation only. These slings are often used for transporting items that are either too bulky or too dangerous to be handled with reusable slings. Once they have been used for a lift, they are discarded. Single-use lifting slings are commonly made of materials such as polypropylene, polyester, or nylon, and they are often preferred in situations where the cost of reusable slings is not justifiable or where there is a need for a quick and efficient lift.

1. Load Capacity

The primary consideration when selecting any lifting sling is its load capacity. It is essential to ensure that the single-use lifting sling you choose can safely handle the weight of the load being lifted. Overloading a lifting sling can lead to failure, resulting in damage to the equipment, injury to workers, or worse, fatalities. To determine the appropriate load capacity, you need to understand the weight of the item to be lifted, including any additional weight from packaging or attachments.

When selecting a single-use lifting sling, always choose one with a higher load capacity than the weight of the load. This safety margin ensures that the sling will not be overstressed during lifting operations. Most lifting slings come with a rating label that specifies their load capacity, which should be checked before each use.

2. Material Selection

The material of the single-use lifting sling plays a significant role in its performance and durability. The most common materials for lifting slings include polyester, nylon, and polypropylene, each offering different strengths, stretch characteristics, and resistance to environmental factors.

- Polyester Slings: Known for their high tensile strength and resistance to wear and tear, polyester slings are widely used in lifting operations. They are resistant to UV rays and can withstand exposure to many chemicals, making them a versatile option.

- Nylon Slings: Nylon slings are known for their excellent elasticity, which can help absorb shock loads during lifts. However, they are sensitive to UV light and certain chemicals, so they may not be suitable for all environments.

- Polypropylene Slings: Polypropylene is a more affordable option, but it has a lower tensile strength compared to polyester and nylon. It is resistant to water and mildew but not to UV light, which can degrade the material over time.

When choosing a single-use lifting sling, consider the environment in which it will be used, including exposure to chemicals, moisture, and UV light. This will help determine the most suitable material for the job.

3. Sling Design and Type

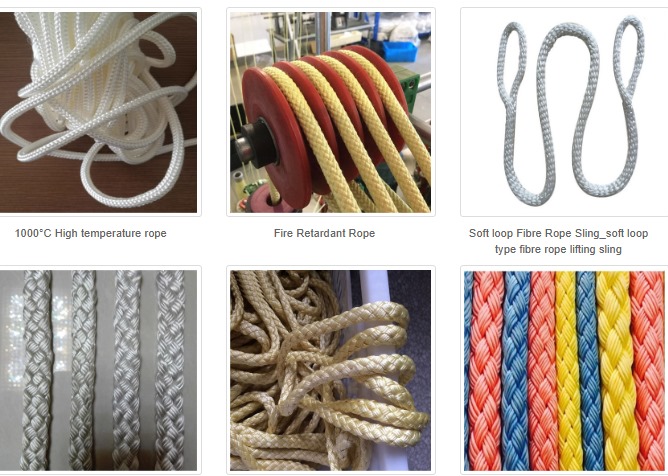

Lifting slings come in various designs, each suited for specific lifting operations. The most common types of lifting slings include:

- Flat Slings: Flat slings are the most basic design, consisting of a single strip of material. They are versatile and can be used for a wide range of lifting applications.

- Round Slings: These slings are made from a continuous loop of fiber, providing additional strength and flexibility. Round slings are ideal for lifting items with smooth or delicate surfaces.

- Webbing Slings: Webbing slings consist of a flat strip of material woven into a strong, flexible sling. These slings are commonly used for heavier loads or applications that require added strength and stability.

The design and type of sling you choose will depend on the specific lifting requirements. For example, flat slings are ideal for general-purpose lifting, while round slings are better suited for handling delicate or irregularly shaped loads.

4. Environmental Considerations

The environment in which the lifting operation takes place can significantly impact the performance of the single-use lifting sling. Factors such as temperature extremes, moisture, and exposure to chemicals should be carefully evaluated before selecting a sling.

- Temperature: Some lifting slings can degrade or lose strength when exposed to high or low temperatures. If the lifting operation takes place in an environment with extreme temperature fluctuations, you may need to select a sling made from a material that can withstand these conditions, such as polyester.

- Moisture: If the sling will be used in wet conditions, it is important to choose a material that is resistant to water absorption and mildew. Polyester and polypropylene slings are good options for wet environments.

- Chemical Exposure: In industrial settings where slings may come into contact with chemicals, it is essential to choose a sling made from a material resistant to chemical degradation. Nylon, for example, can be affected by certain acids, so polyester slings might be a better choice for such environments.

5. Regulatory Compliance and Certification

Lifting slings must meet specific regulatory standards to ensure safety during lifting operations. These standards vary by country and industry but generally address factors such as load capacity, material quality, and performance under stress.

Before selecting a single-use lifting sling, verify that it complies with the relevant safety standards in your region. In the United States, for example, lifting slings must comply with OSHA (Occupational Safety and Health Administration) regulations and ANSI (American National Standards Institute) standards. In the European Union, lifting slings must conform to EN standards.

Choosing a certified single-use lifting sling ensures that it has been tested and approved for safety, minimizing the risk of failure during lifting operations.

6. Cost vs. Quality

While single-use lifting slings are often more affordable than reusable slings, it is important not to compromise on quality in favor of a lower price. Choosing a cheap sling may save you money upfront, but it could lead to costly accidents, equipment damage, or injuries in the long run.

Look for slings that offer a balance between cost and quality. Consider the material, load capacity, and certification when evaluating the cost of the sling. Investing in high-quality slings can help prevent accidents and ensure the safety of your workers.

7. Proper Storage and Handling

Even though single-use lifting slings are designed for one-time use, proper storage and handling are still crucial. Slings should be stored in a dry, cool area away from direct sunlight, chemicals, or abrasive surfaces. Improper storage can lead to premature degradation of the sling, making it unsafe for use even before its first lift.

Before using a single-use lifting sling, inspect it thoroughly for any signs of damage, such as cuts, abrasions, or fraying. Using a damaged sling can significantly reduce its load capacity and increase the risk of failure during lifting operations.

Conclusion

Selecting the right single-use lifting sling is essential for ensuring safe and efficient lifting operations. By considering factors such as load capacity, material, sling design, environmental conditions, regulatory compliance, cost, and proper handling, you can make an informed decision that minimizes risks and enhances productivity. Always prioritize safety and quality when choosing a single-use lifting sling to protect your workforce, equipment, and reputation.