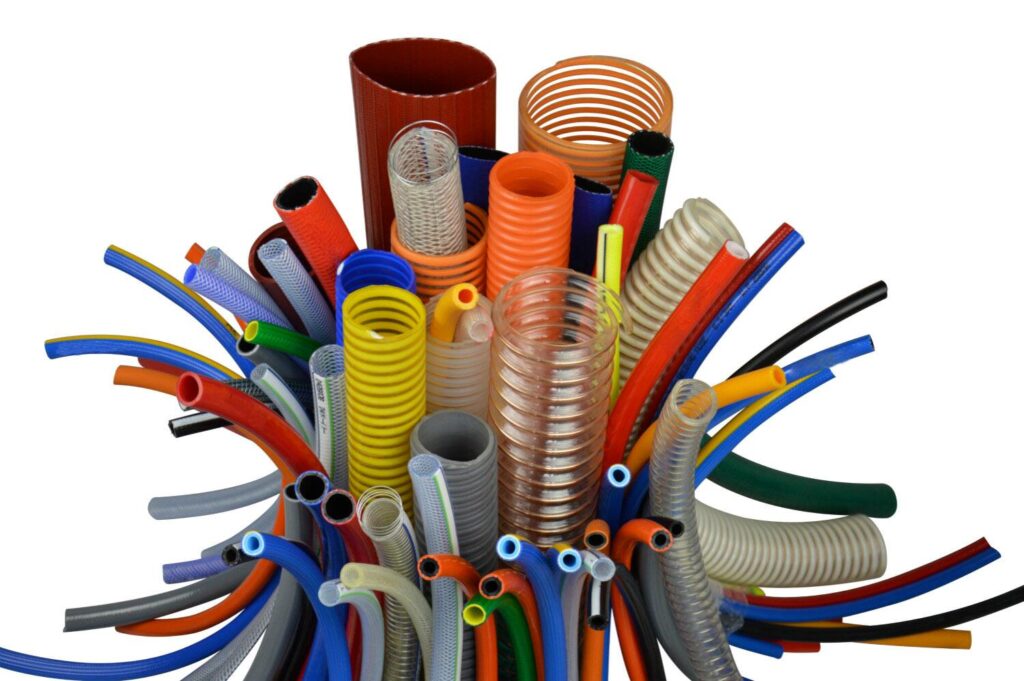

As industries evolve and face new challenges, the demand for advanced solutions in material handling and fluid transport continues to rise. PVC HOSE Manufacturer, known for their versatility, durability, and cost-effectiveness, are at the forefront of this transformation. This article explores the emerging trends in PVC hose technology, examining how innovations are reshaping their application in various industrial sectors.

1. Smart Hose Technology

The integration of smart technology into PVC hoses is revolutionizing their functionality and usability.

- IoT Connectivity: Manufacturers are increasingly incorporating Internet of Things (IoT) technology into PVC hoses. This allows for real-time monitoring of critical parameters such as pressure, temperature, and flow rates. By connecting hoses to a centralized system, users can gain valuable insights into their operations, enabling better decision-making and improved efficiency.

- Predictive Maintenance: Smart hoses equipped with sensors can provide data analytics that help predict when maintenance is needed. This proactive approach minimizes downtime, reduces costs, and ensures that operations run smoothly.

2. Sustainability and Eco-Friendly Materials

With growing concerns over environmental impact, the PVC hose industry is shifting towards more sustainable practices.

- Recyclable Materials: Manufacturers are exploring the use of recyclable PVC formulations in hose production. By developing hoses that can be recycled at the end of their lifecycle, the industry can reduce plastic waste and promote a circular economy.

- Bio-Based Additives: The incorporation of bio-based additives in PVC hoses is becoming more common. These additives can improve the environmental profile of hoses while maintaining performance and durability.

3. Customization and Specialization

The increasing demand for customized solutions is driving manufacturers to offer tailored PVC hoses for specific applications.

- Bespoke Designs: Companies are now able to create hoses that meet unique specifications for various industries, including food and beverage, pharmaceuticals, and chemicals. This customization ensures that the hoses can withstand specific conditions, such as temperature fluctuations or exposure to aggressive substances.

- Color-Coded Hoses: To enhance safety and efficiency, manufacturers are producing color-coded PVC hoses for different applications. This visual differentiation helps operators quickly identify hoses used for specific tasks, reducing the risk of cross-contamination.

4. Enhanced Durability and Performance

Innovations in material science are leading to the development of PVC hoses with improved durability and performance characteristics.

- Multi-Layer Construction: Manufacturers are increasingly utilizing multi-layer construction techniques to enhance the strength and flexibility of PVC hoses. This construction allows for the incorporation of different materials, each designed to optimize specific performance characteristics.

- Improved Chemical Resistance: Advances in formulation technology have led to the development of PVC hoses with enhanced chemical resistance. This allows for their use in more demanding environments, such as chemical processing and industrial manufacturing.

5. Automation in Manufacturing Processes

The adoption of automation in PVC hose manufacturing is improving efficiency and product quality.

- Robotic Assembly Lines: The use of robotic systems in the production process helps streamline operations, reduce labor costs, and minimize human error. Automated systems can handle repetitive tasks, such as cutting and packaging, allowing workers to focus on more complex activities.

- Real-Time Quality Control: Advanced quality control systems using machine learning algorithms are becoming common in PVC hose manufacturing. These systems can monitor production in real time, identifying defects and ensuring consistent quality across batches.

6. Regulatory Compliance and Safety Standards

As industries face increasing scrutiny regarding safety and environmental regulations, PVC hose manufacturers are prioritizing compliance.

- Certifications: Many manufacturers are pursuing certifications to meet industry standards, such as FDA approval for food-grade hoses or RoHS compliance for environmental safety. These certifications help build trust with customers and ensure that products meet regulatory requirements.

- Safety Features: Innovations in design are leading to the incorporation of safety features in PVC hoses, such as burst-resistant technology or anti-static properties. These enhancements reduce the risk of accidents and improve overall safety in industrial applications.

7. Global Market Expansion

The PVC hose industry is witnessing growth in emerging markets, creating new opportunities for manufacturers.

- Market Penetration: Manufacturers are expanding their reach into developing regions where industrial growth is on the rise. By tailoring products to meet the specific needs of these markets, companies can capture a larger share of the growing demand for PVC hoses.

- Local Partnerships: Collaborating with local distributors and manufacturers can facilitate market entry and enhance supply chain efficiency. This approach enables companies to adapt to regional requirements while building strong relationships with customers.

Conclusion: The Future of PVC Hoses

The future of PVC hose technology is bright, driven by advancements in smart technology, sustainability, customization, and automation. As industries continue to evolve, the demand for innovative, high-performance PVC HOSE Manufacturer will only increase.

By embracing these emerging trends, manufacturers can enhance their product offerings, improve operational efficiency, and meet the diverse needs of their customers. The continued focus on sustainability and regulatory compliance will further shape the future of the PVC hose industry, ensuring that it remains a vital component of various industrial applications for years to come.